One of the most critical processes for companies, in both time and cost, is the logistics and supply chain management process. When a company decides to ship their products from one country to another, they must apply and obtain the right documentation, buy insurance, hire lawyers to mitigate legal risks, and ensure that the company who is handling the transportation is to be trusted.

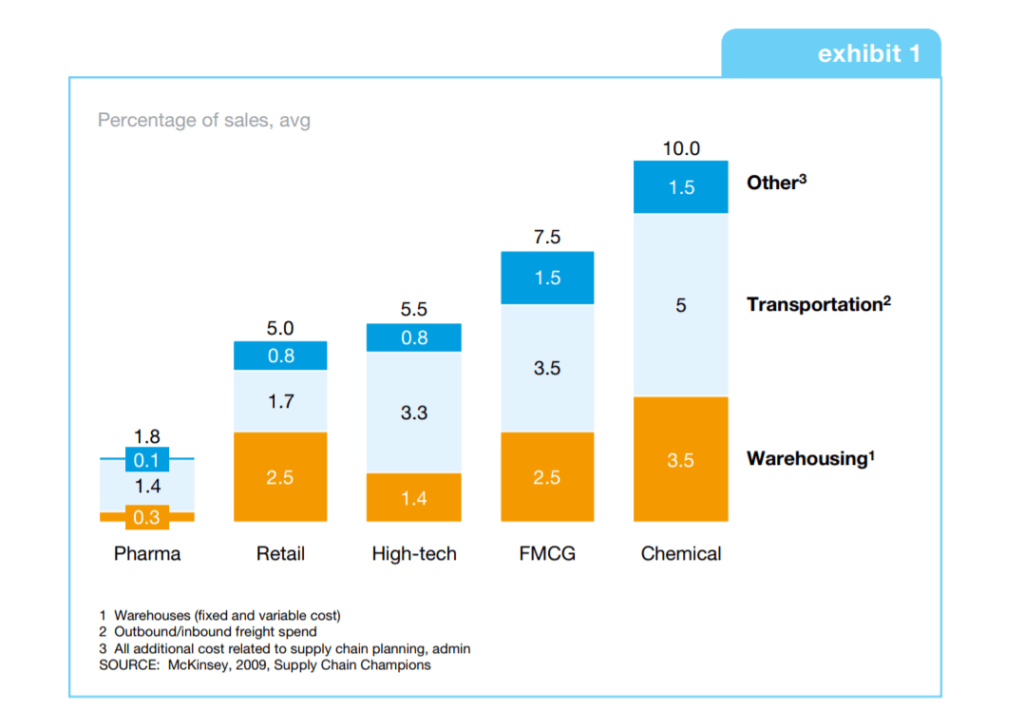

First, the process is costly and is a burden on companies’ bottom lines. The costs, as a percentage of sales (revenue), associated with this part of the business range from 1.8% to 10%, according to an analysis conducted by McKinsey. To put these numbers into perspective, that represents $8,500 million for Nestle.

Secondly, the supply chain process is time-consuming and adds additional risk to operations. For instance, a container might stay in a port for days, if not weeks, due to the fact that there is a “bureaucratic problem” which has to be resolved by sending mails back and forth from one side of the world to the other (though generally not email – most contracts and certifications are still in paper format), as every party has to ensure that the documentation is truthful and complies with the law.

Also, if there’s a problem with the goods, it’s difficult for management to pinpoint where that problem occurred, leading to companies wasting time investigating the issues. Many companies of course insure their products, but nonetheless, damages can be more widespread, such as affecting the reputation of the producer if the delivery cannot be fulfilled (in the case of food spoilage). Last but not least, inventory stock management in-store and in-warehouse also takes time.

Some of these problems can be mitigated – by pinpointing the source of the issue, removing delays in obtaining the correct certificates, and proving the authenticity of the product – using a blockchain solution. Blockchain solutions prove the integrity of data by providing unforgeability, accessibility, automation, transparency, immutability, and a trust-less ecosystem.

Ref: The Economist.

The simplest example lies in the fake clothing industry, worth $450 billion (2.5% of global import). Fake products damage the image of brands such as Louis Vuitton – leading to a decrease in demand for their products, as people may choose the cheaper, fake options, or avoid the genuine options for fear that they may be faked. Below, we describe two examples of how blockchain technology enables businesses to avoid counterfeit goods while also decreasing operating costs. To provide info on who produced the products, where they come from, and to ensure they are genuine, these blockchain solutions provide proof of authenticity.

Those directly involved in the transportation of goods themselves should find blockchain technology useful to their work. Truckers, for example, may experience delays in picking up goods from a port or warehouse on their route, which could cost them money due to them being late for their own deliveries, when the delays aren’t even their own fault. With the use of blockchain technology, it would be transparent to everyone that the trucker wasn’t at fault for the delay, and they may be entitled to compensation for the delays, or will at the very least not have their reputation tarnished due to events outside of their control. This is one logistics issue that Block Array (ARY) is looking to solve with their FreightTrust TMS platform (read our Block Array analysis here).

Examples

We’ll now look at two projects that aim at tackling these problems using blockchain technology – Waltonchain and Modum. However, many more solutions such as VeChain (VEN/VET) exist (read our analysis here).

Example 1) Waltonchain (WTC) and RFID tech

Waltonchain aims at combining Radio Frequency Identification (RFID) technology with the blockchain to assist in supply chain management. RFID technology enables products and objects to communicate between themselves via frequencies (thus, without the need of physical or optical contact). The use of the blockchain, as described by the Walton team, enables the creation of an authentic, trustworthy, traceable, and fully transparent business ecosystem with fully shared data.

RFID tags are often found on books in libraries and book-stores to avoid shop-lifting. We also find this technology being used in the food supply chain and other industries. It’s worth noting that the Walton team is not only developing their own blockchain but also their own RFID chips and scanners.

The Waltonchain team decided to target the clothing industry first. Down the line, they aim to reach all supply chain segments across other industries.

How does Waltonchain work?

Each product is given a unique blockchain ID and RFID tag which is not reusable; once the tag is removed from the product, the tag is void and cannot send any new information on the blockchain. The tag contains, uniquely, a signature key to sign the data within the blockchain. Currently, tags cost $0.10 per unit as the data is stored on the tag itself; however, using the blockchain, the cost of RFID tags will drop substantially (below $0.05 according to Walton’s COO) as no data will be stored on the tag itself.

Each time the RFID tag is close to a hardware system (i.e. handheld RFID readers or static scanners), product information is instantly updated on the blockchain. For example, when goods leave the warehouse, the scanners automatically register and log this event. Once in the truck, another scanner registers this. Finally, when the truck arrives at the destination, the scanners recognise that the goods have reached the shop warehouse and this is written into the blockchain. Companies can log as many events of the supply chain and production process as they want.

Finally, the tags enable retailers to obtain plenty of data – enabling them to improve their efficiency, lower costs, and develop strategies. The tags identify the rate at which an item is tried on and taken off the rack, to calculate stock inventory in real time, and enable a faster checkout as the items will be scanned in bulk rather than separately. All this data enables businesses to better forecast sales which are crucial in strategy making.

For more information regarding Waltonchain, please refer to their whitepaper and the official website.

Example 2) Modum (MOD) in the pharmaceutical industry

The European Union has set strict guidelines regarding supply chain logistics of pharmaceutical goods. Companies must prove, by providing regulators with data, that medications have not been exposed to conditions that may have altered their quality (i.e. temperature). Companies unable to provide this data may see their licenses revoked.

Currently, temperature-stabilised trucks and containers are used by companies to obtain the required data. The problem is that the service is not always needed and is expensive, leading to inefficiencies. For instance, medicines that need to be at an ambient temperature do not require the use of these specialist trucks. However, companies still have to rent them to obtain the data.

Modum (MOD) proposes to tackle this problem through a blockchain-based solution and the use of Bluetooth and NFC sensors. The sensors are put into packages and send information regarding the temperature to the blockchain. The data is verifiable by all parties (clients, suppliers, and regulators) at all times via the use of a dashboard (during and after arrival) or on a blockchain explorer.

Currently, Modum focuses on temperature sensors; however, in its later stages, the company aims at developing other sensors (motion, humidity, etc). Unlike Waltconchain, Modum sensors enable the tracking of the state of the product rather than simply its geographical location.

How does Modum work?

When the company prepares for shipment, sensors are inserted into packages, QR codes are scanned, product data is updated, and alarms are set up via a surveillance dashboard. Once all the data has been finalised, a smart contract is set up and signed by the recipient of the package, and from that moment, the data is on the blockchain and cannot be changed.

During transit, the sensors record environmental conditions that the products are subject to, and data is transmitted to the blockchain – meaning that it cannot be altered or deleted. When a problem occurs regarding, for example, the on-board temperature, an alarm is triggered and notifications are sent to the surveillance dashboards of all parties.

Once the recipient receives the package, and as long as no alarms were triggered, the smart contract is activated and the firm that sent the package is paid. The client can at all times log on to the blockchain and verify that no temperature-related problem occurred during transportation.

Benefits

The benefits of using blockchain technology in the pharmaceutical industry are multiple. First and foremost, this solution is very cost-effective as the company would need to buy sensors rather than rent truck services to comply with the law. Secondly, fake medication is a problem that many countries encounter, so clients and pharmacist would be able to verify that the medications are genuine.

For more information regarding MODUM, please refer to their whitepaper.

The benefits of blockchain in the supply chain industry:

The main advantage of the blockchain is its immutability – meaning that when something is written to it, the data is permanently stored and can never be changed. Unlike traditional databases where data can be forged, deleted, or changed, blockchain technology enables you to be sure that what is on it is the genuine article. This is of use to regulators, companies, and consumers, who can be assured of the legitimacy of data or products; for instance, if a product is said to be made in EU, you can be sure that the EU is its true origin.

The blockchain also enables accessibility and transparency between untrusted parties as all transactions are recorded on a public ledger. Due to the immutability of the blockchain, data, once on it, cannot be changed or interfered with, and additional smart contracts can automate processes which previously may have been based on trust and reliability alone.

With the use of the blockchain, we may be sure of ethics and responsibility, simply by scanning a QR code or by accessing the blockchain. This way, the problems of document falsification and a mutual lack of trust are eradicated, and transparency brought to the supply chain process.

Conclusion:

Many industries and governments would benefit from incorporating blockchain technology. According to the 2017 Situation Report on Counterfeiting and Piracy in the EU released by Europol, 27% of all products seized (by quantity) at border controls were cigarettes, 9% were toys, and 7% food-related products. This poses a threat to society as these products can be harmful to people’s health – being able to ensure the authenticity of products and their origins at all times would make inspections quicker, cheaper, and more efficient, as well as improving safety standards.

China is currently developing its “One Belt One Road” program (also known as the “Silk Road Economic Belt”), linking China to the rest of Asia and Europe through railway systems and maritime transport. This is just one of many global developments that make being able to ensure the traceability and authenticity of products in our global market more crucial than ever before – especially given the fact that most fake low-quality goods currently come from China and a cluster of countries in the East.

The bottom line is that blockchain logistics applied to the supply chain industry will increase trust among all parties (consumers, retailers, transport companies, etc), and people will know the provenance of all the components of the products they buy.